Aluminum has a density of approximately 2.70 grams per cubic centimeter. This makes it a lightweight yet strong metal.

Aluminum is widely used in various industries due to its unique properties. Its low density makes it ideal for applications where weight reduction is crucial. The aerospace, automotive, and construction industries benefit from aluminum’s strength-to-weight ratio. Aluminum is also resistant to corrosion, which adds to its durability and longevity.

Its excellent thermal and electrical conductivity make it valuable in electronics and heat exchange systems. Recycling aluminum is highly efficient, saving energy and resources. These factors contribute to aluminum’s popularity and widespread use in modern manufacturing and engineering. Understanding aluminum’s density is key to appreciating its versatility and benefits.

Density Of Aluminum

The density of aluminum is a key property that affects its use. This lightweight metal is known for its versatility and strength. Understanding its density helps in various applications, from construction to aerospace.

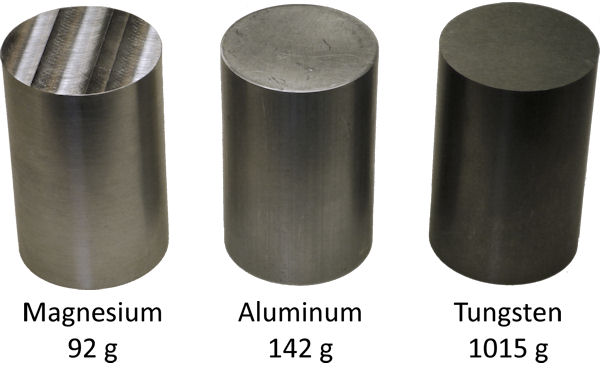

Comparison With Other Metals

Aluminum is much lighter compared to other common metals. Here is a simple comparison:

| Metal | Density (g/cm3) |

|---|---|

| Aluminum | 2.7 |

| Iron | 7.9 |

| Lead | 11.3 |

| Gold | 19.3 |

As seen, aluminum is significantly lighter than iron, lead, and gold. This makes it ideal for industries where weight is crucial.

Units And Measurement

The density of aluminum is usually measured in grams per cubic centimeter (g/cm3). This unit indicates how much mass is present in a given volume. To measure it:

- Weigh the aluminum sample.

- Measure its volume.

- Calculate density using the formula:

Density = Mass / Volume.

For example, if an aluminum block weighs 54 grams and has a volume of 20 cm3, its density is:

Density = 54 g / 20 cm3 = 2.7 g/cm3This confirms the standard density of aluminum, making it easy to verify and use in calculations.

Understanding these units and measurements ensures accurate results in various applications.

Credit: www.sunrise-metal.com

Physical Properties

Understanding the physical properties of aluminum helps us appreciate its versatility. Aluminum is a unique metal with several valuable characteristics. This section explores its weight, strength, and corrosion resistance.

Weight And Strength

Aluminum is known for its light weight. It has a density of about 2.7 g/cm³. This makes it about one-third as dense as steel. Despite being light, aluminum is strong. It has a high strength-to-weight ratio. This is why it is used in aircraft, cars, and buildings.

Here is a table comparing the density of aluminum with other metals:

| Metal | Density (g/cm³) |

|---|---|

| Aluminum | 2.7 |

| Steel | 7.85 |

| Gold | 19.32 |

Corrosion Resistance

Aluminum resists corrosion naturally. It forms a thin oxide layer when exposed to air. This layer protects the metal from further damage. This makes aluminum ideal for outdoor use.

Here are some benefits of aluminum’s corrosion resistance:

- Long-lasting and durable

- Low maintenance costs

- Resistant to weather changes

These properties make aluminum a favorite for many industries. It is used in construction, transportation, and packaging.

Applications In Industry

Aluminum’s density makes it ideal for many industries. Its lightweight nature, paired with strength, offers unique advantages.

Aerospace And Automotive

The aerospace industry values aluminum for its lightweight properties. Aircraft structures use aluminum to reduce weight and fuel consumption. This metal also resists corrosion, increasing the lifespan of parts.

In the automotive sector, aluminum reduces vehicle weight. Lighter cars improve fuel efficiency and reduce emissions. Manufacturers use it in engines, wheels, and body panels.

Construction And Electronics

Aluminum is a popular choice in construction. Its strength and lightness make it suitable for buildings and bridges. Aluminum also resists corrosion, ensuring long-lasting structures.

In electronics, aluminum is crucial. It acts as a heat sink, preventing overheating in devices. Aluminum also forms casings for laptops, tablets, and smartphones.

| Industry | Application | Benefits |

|---|---|---|

| Aerospace | Aircraft structures | Lightweight, corrosion-resistant |

| Automotive | Engines, wheels, body panels | Reduced weight, improved fuel efficiency |

| Construction | Buildings, bridges | Strength, corrosion-resistant |

| Electronics | Heat sinks, casings | Prevents overheating, durable |

Environmental Impact

Aluminum is a popular material due to its light weight and strength. Understanding its environmental impact is crucial. This metal has significant effects on our surroundings. Let’s explore these impacts in more detail.

Recyclability

Aluminum is highly recyclable. Recycling aluminum saves a lot of energy. This process uses only 5% of the energy needed to produce new aluminum. Less energy means lower greenhouse gas emissions. This helps reduce global warming.

Aluminum can be recycled repeatedly without losing its quality. This makes it a sustainable choice. Recycling helps save natural resources. It also reduces the need for mining. Mining can harm the environment. By recycling, we can protect the Earth.

Energy Efficiency

Producing aluminum from raw materials requires a lot of energy. This process is called smelting. Smelting emits a large amount of CO2. But, the energy used in recycling is much lower. This makes recycling aluminum more energy-efficient.

Energy efficiency is crucial for a sustainable future. Using recycled aluminum helps conserve energy. This also reduces the carbon footprint. Less energy use means fewer fossil fuels burned. This helps protect the environment.

| Process | Energy Use | CO2 Emissions |

|---|---|---|

| Smelting | High | High |

| Recycling | Low | Low |

Recycling aluminum is not only energy-efficient but also eco-friendly. It helps in reducing pollution and conserving natural resources.

Future Of Aluminum

The future of aluminum looks promising due to its unique properties. Its lightweight, corrosion resistance, and recyclability make it invaluable. Industries are keen on exploring new applications and enhancing its qualities. Let’s dive into some exciting advancements and market potential.

Innovations And Research

Ongoing research focuses on making aluminum even more efficient. Scientists are developing stronger aluminum alloys that can replace heavier metals. These new alloys will be crucial in the automotive and aerospace industries.

Another area of research is in nanotechnology. By manipulating aluminum at the nano level, we can create materials with enhanced properties. This includes better conductivity, strength, and lighter weight.

Researchers are also working on improving the recycling process of aluminum. Efficient recycling methods reduce energy consumption and environmental impact. This makes aluminum a more sustainable choice for future applications.

Potential Market Growth

The market for aluminum is set to expand in the coming years. Several factors contribute to this growth:

- Automotive Industry: Increased use of aluminum in electric vehicles.

- Aerospace Industry: Demand for lightweight, strong materials.

- Packaging Industry: Shift towards sustainable packaging solutions.

Let’s break down the potential market growth in a table:

| Industry | Growth Driver | Projected Growth |

|---|---|---|

| Automotive | Electric Vehicles | 15% annually |

| Aerospace | Lightweight Materials | 10% annually |

| Packaging | Sustainability | 8% annually |

Investing in aluminum now could yield substantial returns. As industries evolve, the demand for this versatile metal will only increase.

Credit: www.researchgate.net

Credit: www.robotroom.com

Frequently Asked Questions

What Is The Density Of Aluminum?

The density of aluminum is 2. 7 grams per cubic centimeter.

How Does Aluminum’s Density Compare To Steel?

Aluminum is about one-third the density of steel, making it much lighter.

Why Is Aluminum Considered Lightweight?

Aluminum’s density is low, which makes it lightweight and ideal for many applications.

Can Aluminum’s Density Affect Its Strength?

Yes, despite its low density, aluminum can be alloyed for increased strength.

Does Temperature Impact Aluminum’s Density?

Temperature changes can slightly affect aluminum’s density, but it remains relatively stable.

Is Aluminum’s Density Beneficial In Construction?

Absolutely, aluminum’s low density reduces overall weight, making it ideal for construction.

Conclusion

Understanding the density of aluminum is crucial for various applications. Its lightweight nature makes it a popular choice in many industries. Engineers and designers benefit from aluminum’s properties. This metal’s unique characteristics help in creating efficient and durable products. Always consider aluminum for projects requiring strength and lightness.