Measuring and analyzing data from smart construction equipment can be challenging. But it is crucial for improving efficiency and reducing costs in construction projects.

Smart construction equipment is revolutionizing the industry. It collects vast amounts of data to help project managers make informed decisions. By understanding how to measure and analyze this data, you can optimize performance, reduce downtime, and enhance safety. In this blog post, we will explore the steps to effectively gather and interpret data from your smart machinery.

You’ll learn how to leverage this information to improve your construction processes and achieve better results. Let’s dive in and unlock the potential of your smart construction equipment.

Importance Of Data In Smart Construction

Data has become a cornerstone of modern construction projects. Smart construction equipment can collect vast amounts of data. This data can transform the way construction sites operate. It can help in making informed decisions and improving efficiency.

Benefits Of Data Collection

Data collection offers several advantages in construction. Firstly, it provides real-time insights. These insights can help in tracking progress and identifying issues quickly. Secondly, data aids in predictive maintenance. This can reduce downtime and extend the lifespan of equipment. Lastly, data helps in resource management. It ensures that materials and labor are used efficiently.

Impact On Project Efficiency

Data can significantly impact project efficiency. It allows for better planning and coordination. This can lead to faster project completion. Data also helps in cost management. It provides insights into spending patterns and helps in budget control. Furthermore, data enhances safety on construction sites. It can identify hazardous conditions and prevent accidents.

In summary, data from smart construction equipment is invaluable. It can improve efficiency, reduce costs, and enhance safety. Embracing data collection is crucial for modern construction projects.

Types Of Data Collected

Hey friends, today we’re diving into the world of smart construction equipment. One of the most fascinating aspects is the different types of data collected. This data helps in understanding how the equipment is used and how it performs. Knowing this can lead to better decisions on the job site. So, let’s break it down into two main categories: Operational Data and Performance Metrics.

Operational Data

Operational data is all about how the equipment is being used. Think of it like a fitness tracker for your machinery. It tracks everything that happens during a workday. Why is this important? Because it helps you see if the equipment is being used efficiently.

Here’s what operational data typically includes:

- Usage Time: How long the equipment is in use each day.

- Idle Time: Time when the machine is on but not working. Just like you sitting on the couch, doing nothing.

- Fuel Consumption: How much fuel is used. This tells you if your machine is guzzling too much gas.

- Location Tracking: GPS data showing where the equipment is. Useful for keeping track of all your gear.

Performance Metrics

Performance metrics are like the report card for your equipment. They tell you how well the equipment is doing its job. Is it performing at its best, or is there room for improvement?

Common performance metrics include:

- Work Output: Measures what the machine actually accomplishes. Like how many tons of dirt it moves.

- Efficiency: How well the machine converts fuel into work. Higher efficiency means less waste.

- Maintenance Alerts: Notifications when something needs fixing. Like a check engine light in your car.

- Downtime: Time when the equipment is out of service. Less downtime means more work gets done.

So, there you have it. Operational data and performance metrics are the two main types of data collected from smart construction equipment. This data is crucial for making informed decisions on the job site. The good news? It’s easier than ever to get this info with today’s technology. Happy building!

Data Collection Methods

Hey friends! Today, we’ll dive into how we can collect and analyze data from smart construction equipment. It’s easier than you think! We will look at two main methods: using sensors and IoT devices, and manual data entry. Let’s break it down in simple terms.

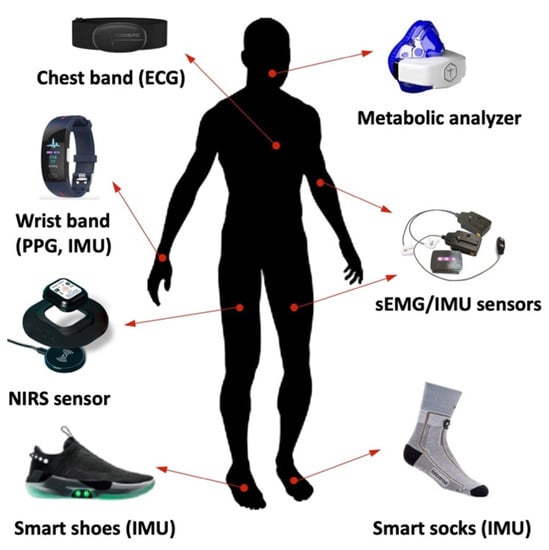

Sensors And Iot Devices

Sensors and IoT (Internet of Things) devices are like the eyes and ears of your construction equipment. They help gather real-time data without you lifting a finger. These devices are attached to the machines to collect data like:

- Usage hours: How long a machine has been running.

- Fuel consumption: How much fuel is being used.

- Location tracking: Where your equipment is at any given time.

- Performance metrics: How well the equipment is performing.

Think of it like a fitness tracker for your construction equipment. Just like your fitness tracker tells you how many steps you’ve taken, these sensors tell you what your machines are up to. Pretty cool, right?

Manual Data Entry

Sometimes, you need to gather data the old-fashioned way—by manually entering it. This method is great for capturing information that sensors might miss. For example:

- Maintenance records: When was the last service?

- Operator logs: Who used the machine and for how long?

- Incident reports: Any accidents or issues?

I remember a project where we used a simple spreadsheet to log daily equipment usage. It was straightforward and helped us keep track of everything. The good news? You don’t need fancy tools. Sometimes, a pen and paper or a basic spreadsheet does the job.

So, whether you’re using high-tech sensors or jotting down notes manually, collecting data from your smart construction equipment is essential. It helps you understand how your machines are performing and where you can improve.

In the next section, we’ll talk about how to analyze this data. Stay tuned!

Credit: www.mdpi.com

Tools For Data Measurement

Measuring and analyzing data from smart construction equipment is crucial. It helps in improving efficiency and reducing costs. Using the right tools is essential for accurate data collection. These tools fall into two main categories: software solutions and hardware tools.

Software Solutions

Software solutions play a vital role in data measurement. They collect, analyze, and present data in a user-friendly way. One popular option is Construction Management Software (CMS). It integrates with various equipment to gather data in real-time. Another tool is Building Information Modeling (BIM) software. BIM helps in visualizing and managing construction data.

Fleet management software is also important. It tracks equipment usage, fuel consumption, and maintenance schedules. These software solutions offer dashboards and reports. They help in making informed decisions.

Hardware Tools

Hardware tools are equally important for data measurement. Sensors are a primary hardware tool. They monitor different parameters like temperature, pressure, and load. GPS devices track equipment location and movement. This data is crucial for project planning and execution.

Telematics systems are another essential hardware tool. They collect data from equipment and send it to the cloud. This data can be accessed remotely. Drones and cameras are also used for data collection. They provide visual data for site monitoring and inspection.

Combining software and hardware tools ensures accurate data measurement. It leads to better project management and efficiency.

Data Analysis Techniques

Hey friends, today we’re going to dive into Data Analysis Techniques for smart construction equipment. Knowing how to measure and analyze data from your equipment can save you time and money. It can also improve your construction projects. So, let’s explore some easy ways to look at your data.

Descriptive Analytics

First up, let’s talk about Descriptive Analytics. This technique is like looking at a snapshot of your data. It helps you understand what has happened over a certain period.

Think of it like reading a report card. You see your grades and attendance. Descriptive analytics looks at things like:

- Total hours the equipment was used

- Fuel consumption over a month

- Number of times maintenance was needed

These stats can tell you if your equipment is being used efficiently. Are you getting the most out of your machines? Or are they sitting idle too often?

Predictive Analytics

Now, let’s move on to Predictive Analytics. This is where things get a bit more exciting. Predictive analytics looks at your data and tries to forecast what might happen in the future.

Remember the weather forecast? You look at it to plan your day. Predictive analytics does something similar for your equipment. It can tell you:

- When a machine might break down

- How much fuel you’ll need next month

- If your project will finish on time

How does it do this? It uses past data to find patterns. For example, if a machine usually breaks down after 1000 hours of use, you can plan maintenance before it hits that mark.

This way, you avoid surprises and keep your project on track.

So, to wrap it up, using these data analysis techniques can make your work easier. You’ll know more about your equipment and can plan better. Give it a try and see the difference for yourself!

Key Performance Indicators (kpis)

Hey friends, today we’re diving into a topic that’s very important for construction projects: Key Performance Indicators (KPIs). KPIs help us understand how well our smart construction equipment is doing. They show us the good and the bad. Let’s break down two main types of KPIs: Efficiency Metrics and Safety Metrics. Ready? Let’s go!

Efficiency Metrics

Efficiency metrics help you see how well your equipment is performing. Think of it like checking the speed and fuel of your car. You want to know if it’s running smoothly and not wasting gas. For construction equipment, we look at:

- Utilization Rate: How much time is the equipment actually working versus just sitting idle?

- Operating Hours: The total hours the equipment is in use. More hours can mean more work done.

- Fuel Consumption: Are you using fuel efficiently? This can save money and reduce waste.

Keeping an eye on these metrics can help you make smarter decisions. You might find that some machines are underused or overused. Adjusting their use can save you time and money. Simple, right?

Safety Metrics

Safety is super important on any construction site. You want everyone to go home safe and sound at the end of the day. Safety metrics help you track how well you’re doing. Here’s what you should look at:

- Incident Rate: The number of accidents or near-misses that occur. Lower is better.

- Compliance Rate: How often safety protocols are followed. High compliance means a safer site.

- Maintenance Records: Keeping your equipment in good shape reduces the risk of accidents.

By tracking these metrics, you can identify potential problems before they become serious. For example, if you notice an increase in incidents, it might be time for extra safety training. Better safe than sorry!

So there you have it, friends. Measuring and analyzing data from smart construction equipment doesn’t have to be complicated. Focus on these key KPIs, and you’ll be on the right track. Stay safe and efficient out there!

Integrating Data With Project Management

Integrating data from smart construction equipment with project management can boost efficiency. It ensures seamless workflow and timely project completion. By merging data with project management tools, you can monitor progress in real-time. This helps in making informed decisions swiftly. Let’s explore how this integration works and its benefits.

Real-time Monitoring

Real-time monitoring allows you to track equipment usage instantly. You can see which machines are operational and which are idle. This helps in reallocating resources to avoid downtime. Real-time data also helps in identifying potential issues early. It ensures that you can address problems before they escalate.

Instant access to equipment data means better project oversight. Managers can adjust schedules based on actual progress. This leads to better time management and project efficiency. With real-time monitoring, you stay on top of every aspect of the project.

Decision-making Support

Data integration aids in making better decisions. Having accurate data at your fingertips means you can plan better. You can analyze equipment performance and maintenance needs. This helps in scheduling maintenance without affecting productivity.

Data-driven decisions lead to cost savings. You can avoid unnecessary repairs and optimize equipment usage. It ensures that resources are used efficiently. Decision-making becomes more accurate and timely with integrated data. This leads to more successful project outcomes.

Credit: www.sciencedirect.com

Challenges In Data Measurement And Analysis

Hey there! So, you’re curious about the challenges of measuring and analyzing data from smart construction equipment? Well, you’re in the right place. Gathering data from these advanced machines isn’t as simple as pushing a button. There are a few hurdles along the way. Let’s dive in and explore some of these challenges together.

Data Accuracy

First up, let’s talk about data accuracy. Imagine you’re baking a cake. If your measurements are off, the cake might not turn out right. It’s the same with data. For construction projects, having accurate data is crucial.

But getting this accuracy can be tough. Why? Because:

- Equipment might be used in different weather conditions.

- There could be wear and tear on the machines.

- Different operators might use the equipment differently.

All these factors can affect the data quality. So, ensuring that the data you collect is spot-on is a real challenge.

Data Security

Next, we have data security. Picture this: You have a treasure chest full of gold. You’d want to keep it safe, right? The same goes for your data. Data from smart construction equipment is valuable. It needs to be protected.

But there are threats out there. Just like pirates might try to steal your treasure, hackers could try to get your data. Here are some common concerns:

- Unauthorized access to data.

- Data breaches.

- Malware attacks.

Keeping your data secure is vital. It’s like putting a strong lock on your treasure chest.

So, those are some of the main challenges in data measurement and analysis. It’s not easy, but with the right tools and strategies, it’s totally doable. And remember, while it might seem like a lot to handle, taking it step by step can make a world of difference. Happy analyzing!

Future Trends In Smart Construction Data

The construction industry is changing fast with smart technology and data analytics. Measuring and analyzing data from smart construction equipment is vital. Future trends in smart construction data are shaping up to be quite exciting. These trends promise to enhance efficiency and accuracy on construction sites.

Ai And Machine Learning

AI and machine learning are transforming construction data analysis. These technologies can predict equipment maintenance needs. This helps to avoid costly downtime. They also analyze patterns to improve safety on site. Smart equipment with AI can make real-time decisions. This increases productivity and reduces errors. Machine learning algorithms can process vast amounts of data quickly. This provides insights that were previously impossible to obtain.

Advanced Analytics

Advanced analytics are playing a crucial role in smart construction. They allow for the integration of various data sources. This provides a comprehensive view of the project. Sensors on equipment collect data continuously. Advanced analytics then process this data to identify trends and anomalies. This helps to improve project planning and execution. Predictive analytics can forecast potential issues before they arise. This proactive approach leads to better resource management.

Incorporating these future trends in smart construction data is essential. It ensures the efficient and safe completion of construction projects. Stay updated with these trends to stay ahead in the industry.

Credit: www.sciencedirect.com

Frequently Asked Questions

What Is Data Analysis In Construction?

Data analysis in construction involves collecting and examining project data. It helps improve efficiency, reduce costs, and ensure project success.

What Is Komatsu Smart Construction?

Komatsu Smart Construction is an advanced technology solution integrating machinery, drones, and data for efficient construction site management. It enhances productivity, accuracy, and safety.

What Is Smart Construction Equipment?

Smart construction equipment integrates advanced technology for improved efficiency, safety, and productivity. These machines collect data to monitor performance, usage, and maintenance.

How To Collect Data From Smart Construction Equipment?

Data from smart construction equipment is collected using sensors and IoT devices. These devices transmit data to central systems for analysis.

Conclusion

Measuring and analyzing data from smart construction equipment is essential. It boosts efficiency and reduces costs. Use the right tools and software. Gather data accurately and consistently. Analyze trends to make informed decisions. Regular updates and training are vital. This ensures your team stays skilled.

Smart equipment offers valuable insights. Use them to improve your projects. Stay ahead in the construction industry. Embrace smart technology for better results.

Rakib Sarwar is a seasoned professional blogger, writer, and digital marketer with over 12 years of experience in freelance writing and niche website development on Upwork. In addition to his expertise in content creation and online marketing, Rakib is a registered pharmacist. Currently, he works in the IT Division of Sonali Bank PLC, where he combines his diverse skill set to excel in his career.