To measure and calculate concrete volume for construction, start by determining the area’s dimensions. Then, use a simple formula to find the volume needed.

Concrete is essential for many construction projects. Accurate measurements ensure you have enough material and avoid waste. Whether you’re building a foundation, a driveway, or a wall, knowing how to calculate the concrete volume is crucial. This process involves measuring the length, width, and depth of the area.

Once you have these dimensions, you can use a formula to calculate the volume. Understanding this process saves time and money, ensuring your project runs smoothly. Let’s explore the steps to measure and calculate the concrete volume correctly.

Introduction To Concrete Volume Calculation

Concrete volume calculation is a fundamental step in construction projects. Accurate measurements ensure the right amount of concrete for stability and cost-efficiency. This guide will help you understand the basics of calculating concrete volume.

Importance In Construction

Calculating concrete volume is crucial for several reasons. It helps in estimating the cost of materials. Knowing the volume ensures you order the right amount. This prevents wastage and saves money. It also helps in planning the work schedule. With accurate measurements, construction can proceed smoothly.

Basic Concepts

Understanding the basic concepts is essential. Concrete volume is measured in cubic units. For example, cubic meters or cubic feet. The formula to calculate volume is simple. Multiply length, width, and height. This gives the total volume of concrete needed.

Let’s break it down. Suppose you have a slab of concrete. The length is 10 meters, the width is 5 meters, and the height is 0.2 meters. The volume is 10 x 5 x 0.2 = 10 cubic meters. Always double-check your measurements. Accurate data ensures the right amount of concrete.

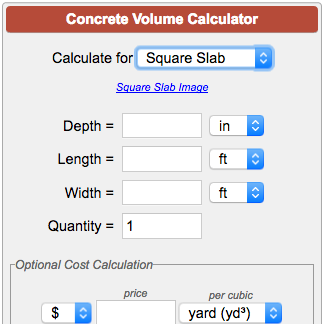

Credit: www.calculatorsoup.com

Tools And Materials Needed

Hey friends, today we are diving into the world of concrete! Specifically, how to measure and calculate concrete volume for your construction projects. But before we get into the calculations, let’s talk about the tools and materials needed. Having the right tools and materials is crucial. It makes the process easier and ensures accuracy. Let’s get started!

Measurement Tools

First things first, you need the right measurement tools. Measuring concrete isn’t just about eyeballing it. You need precision. Here are some tools you’ll need:

- Measuring Tape: A sturdy tape measure is essential. It helps you measure the dimensions of the area accurately.

- Laser Distance Meter: If you want to be super precise, a laser distance meter can be a good investment.

- Level: A level ensures that your measurements are straight and level, which is very important in construction.

- Calculator: A simple calculator can help you with quick calculations on-site.

Required Materials

Now that we’ve got the tools covered, let’s talk about the materials. To measure and calculate concrete volume, you need to consider the materials you’ll be using:

- Concrete Mix: This is the actual material you’ll be measuring. You can buy pre-mixed concrete or mix your own using cement, sand, and gravel.

- Formwork: These are the molds that hold the concrete in place until it hardens. They need to be measured accurately to ensure the right volume of concrete.

- Water: Water is a key ingredient in mixing concrete. Too much or too little can affect the consistency and strength of the concrete.

And there you have it! With the right tools and materials, you are well on your way to accurately measuring and calculating concrete volume for your construction projects. Stay tuned for more tips and tricks on making your construction work as smooth as possible.

Steps To Measure Concrete Volume

Hey there! So, you need to measure and calculate the concrete volume for your construction project, huh? Don’t worry, it’s not as complicated as it sounds. With a few simple steps, you’ll be able to figure out exactly how much concrete you need. Let’s dive into the steps to measure concrete volume and make it super easy for you to understand. Ready?

Site Preparation

First things first, you need to prepare your site. This step is crucial because it sets the foundation (no pun intended!) for accurate measurements.

- Clear the area: Remove any debris, plants, or obstacles from the area where you’ll be pouring concrete.

- Level the ground: Ensure the ground is as level as possible. You can use a shovel, rake, or even a small bulldozer for larger projects.

- Mark the boundaries: Use stakes and string to mark the edges of the area. This will help you measure dimensions accurately.

Remember, a well-prepared site makes the rest of the process much smoother. Trust me, I’ve learned this the hard way!

Measuring Dimensions

Now that your site is ready, it’s time to measure the dimensions. This is where the magic happens – or rather, the math.

- Measure the length and width: Use a measuring tape to find the length and width of the area. Write these numbers down.

- Calculate the area: Multiply the length by the width to get the total area. For example, if your area is 10 feet long and 5 feet wide, the area is 50 square feet.

- Measure the depth: Decide how thick you want the concrete to be. Common depths are 4 inches for patios and 6 inches for driveways. Convert this measurement to feet (e.g., 4 inches = 0.33 feet).

And here’s a pro tip: double-check your measurements. It’s always better to measure twice and pour once. You’ll thank yourself later!

Once you have all these measurements, you can easily calculate the concrete volume needed. Just multiply the area by the depth. For our example, 50 square feet x 0.33 feet = 16.5 cubic feet of concrete. Simple, right?

Stay tuned for the next part where we’ll talk about ordering the right amount of concrete and some handy tips for pouring it. Happy building!

Credit: www.calculatorsoup.com

Calculating Volume For Different Shapes

When it comes to construction, getting the right amount of concrete is super important. You don’t want too much or too little. So, how do you figure out the right volume? It’s simple! First, you need to know the shape of the area you’re working with. Let’s break it down into three common shapes: rectangular slabs, cylindrical columns, and irregular shapes.

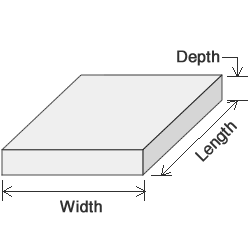

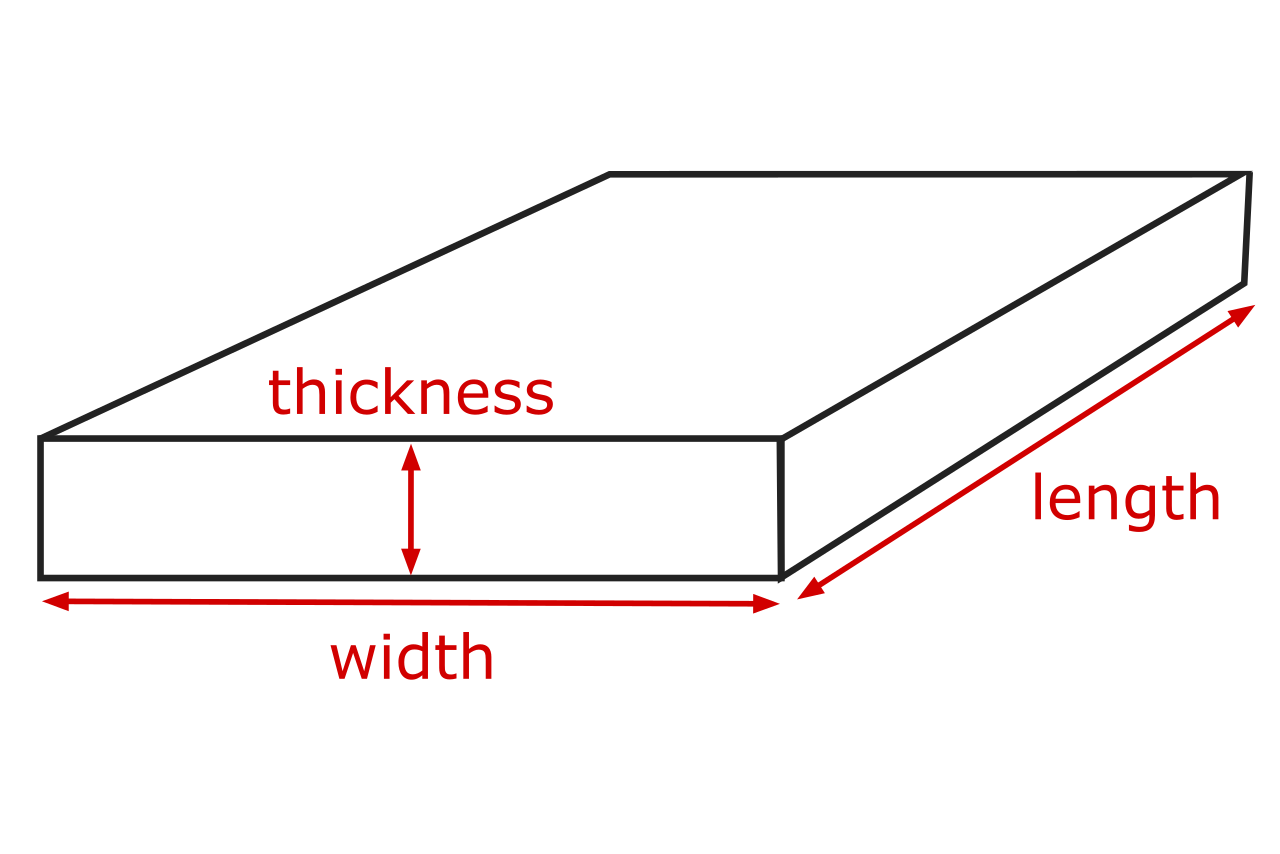

Rectangular Slabs

Think of a rectangular slab like a big, flat box. You need to know three things: the length, the width, and the height (or thickness). Here’s a simple formula to use:

For example, if your slab is 10 meters long, 5 meters wide, and 0.2 meters thick, the volume would be:

Volume = 10m x 5m x 0.2m = 10 cubic meters

Easy, right? Just measure, multiply, and you’ve got your concrete volume for a rectangular slab.

Cylindrical Columns

Next up, cylindrical columns. These are like tall cans. To find the volume, you need the radius (half the diameter) and the height. The formula looks like this:

Here’s a quick example. If your column has a radius of 0.5 meters and a height of 3 meters, your calculation would be:

Volume = 3.14 x (0.5m)² x 3m ≈ 2.355 cubic meters

So, for cylindrical columns, just remember to use π (about 3.14) and square the radius before you multiply by the height.

Irregular Shapes

Now, irregular shapes can be a bit tricky. They don’t have simple formulas. But don’t worry, there are ways to handle them. One method is to break the irregular shape into smaller, regular shapes. Then, calculate the volume for each small shape and add them up.

For instance, if you have a weird-shaped foundation, you might divide it into several rectangular slabs and triangular prisms. Calculate the volume for each part and sum them up:

- Rectangular part: Volume = Length x Width x Height

- Triangular prism part: Volume = (1/2 x Base x Height) x Length

By adding these volumes together, you get the total volume for the irregular shape. It might take a bit more time, but it’s worth it to get the concrete volume just right.

And there you have it! Calculating concrete volume for different shapes is not as hard as it seems. Just remember the basic formulas and break down the complex shapes. Happy building!

Adjusting For Waste And Variability

Calculating concrete volume accurately involves adjusting for waste and variability. This ensures sufficient material for the project, reducing the risk of shortages. Accurate measurement is essential for cost efficiency and project success.

Concrete volume calculation isn’t always precise. Variability and waste can affect the final volume needed. Extra measures are essential to ensure the project runs smoothly.Adding Extra Volume

Adding extra volume accounts for unexpected losses. It ensures you don’t run short. A common practice is to add 5-10% more concrete. This helps cover spillage, over-excavation, and minor errors in measurement.Considering Material Properties

Concrete materials have unique properties. These can influence the final volume. Some materials may shrink or expand. Consider these changes when calculating volume. Knowing the specific properties of your materials helps in making accurate adjustments. By accounting for waste and variability, your concrete project is more likely to succeed. This approach saves time and money in the long run. “`

Credit: www.inchcalculator.com

Common Mistakes To Avoid

Measuring and calculating concrete volume is crucial for any construction project. But, many make common mistakes that lead to costly errors. Avoiding these mistakes ensures your project stays on budget and on time.

Inaccurate Measurements

One of the biggest mistakes is inaccurate measurements. Always double-check your measurements. Use the right tools. A small error can lead to a big problem. Measure the length, width, and depth accurately. Mistakes in these can lead to too much or too little concrete.

Ignoring Site Conditions

Do not ignore site conditions. They greatly affect the amount of concrete needed. Different soils, weather conditions, and load requirements change everything. Ignoring these can lead to weak structures. Always take the site conditions into account. Consult with a professional if unsure.

Using Software And Online Calculators

Hey friends, today we are diving into a very practical topic: measuring and calculating concrete volume for construction. If you have ever been involved in a construction project, you know how crucial it is to get the measurements right. But what if we told you that there are tools available to make this process a whole lot easier? Yes, you heard it right! Using software and online calculators can simplify the task and save you time. Let’s explore this in more detail.

Benefits Of Digital Tools

Using digital tools for calculating concrete volume comes with several benefits:

- Accuracy: Digital tools minimize human errors, ensuring your measurements are spot-on.

- Time-saving: These tools speed up the process, allowing you to focus on other important tasks.

- Ease of Use: Most software and online calculators are user-friendly, making them accessible even for beginners.

- Cost-effective: Avoiding over-purchasing or under-purchasing concrete saves money in the long run.

In my own experience, using an online calculator has significantly reduced the stress and guesswork involved in my projects. It’s like having a personal assistant who never makes a mistake!

Popular Software Options

Now, let’s look at some popular software options that can help you calculate concrete volume:

- Concrete Calculator by Titan: This software is great for both small and large projects. It allows you to input dimensions and get an instant volume calculation.

- Construction Master Pro: A handheld calculator that’s super handy on-site. It’s designed specifically for construction pros.

- PlanSwift: This is more comprehensive software that not only calculates concrete volume but also helps with other aspects of construction planning.

- Online Calculators: Websites like CalculatorSoup offer free tools that are easy to use and highly accurate.

Each of these tools has its own strengths. The good news? You can choose one that fits your specific needs and project scale.

Remember, the right tool can make a huge difference. So next time you’re about to measure and calculate concrete volume, give these digital tools a try. You’ll wonder how you ever managed without them!

Practical Examples And Case Studies

Understanding how to measure and calculate concrete volume is crucial for any construction project. This knowledge ensures precise planning and cost estimation. In this section, we will explore practical examples and case studies to give you a clear picture of how to apply these calculations in real-world scenarios.

Residential Projects

Imagine you are building a small patio in your backyard. First, measure the length, width, and depth of the area. Let’s say the patio is 10 feet long, 8 feet wide, and 0.5 feet deep. To find the volume, multiply these dimensions: 10 x 8 x 0.5 = 40 cubic feet. This calculation helps you determine how much concrete you need for your patio.

Another example is constructing a driveway. If the driveway is 20 feet long, 12 feet wide, and 0.75 feet deep, the volume calculation would be: 20 x 12 x 0.75 = 180 cubic feet. Knowing this volume helps you plan your materials and budget effectively.

Commercial Projects

Consider a commercial building’s foundation. Suppose the foundation needs to cover an area of 100 feet by 50 feet, with a depth of 1 foot. The volume calculation would be: 100 x 50 x 1 = 5,000 cubic feet. This volume is essential for planning the concrete supply.

Another example is a large parking lot. If the parking lot is 200 feet long, 150 feet wide, and 0.5 feet deep, the volume would be: 200 x 150 x 0.5 = 15,000 cubic feet. Knowing this helps in efficient project management.

By understanding these practical examples, you can apply the same principles to any construction project. Accurate volume calculations ensure efficient use of materials and cost management.

Tips For Accurate Measurements

Hey there, fellow builders! Getting your concrete measurements right is super important. Why? Because even a small mistake can mess up your whole project. But don’t worry, I’ve got some simple tips to help you measure and calculate concrete volume accurately. Let’s dive in.

Double-checking Data

First things first, always double-check your data. This might sound boring, but it’s crucial. Imagine you’re baking a cake. You wouldn’t want to forget the sugar, right? Same with concrete. Double-checking ensures you have the right amount of materials.

Here’s a quick checklist to make sure you’re on track:

- Re-measure the length, width, and height of the area where you’ll pour concrete.

- Make sure your measurements are in the same units (feet, meters, etc.).

- Use a reliable calculator to confirm your volume calculations.

Trust me, taking a few extra minutes to double-check can save you a lot of headaches later.

Professional Help

Sometimes, it’s just better to call in the pros. If you’re unsure about your calculations or measurements, don’t hesitate to ask for help. Professional contractors and engineers have the experience to get it right the first time.

Here are some reasons why professional help can be beneficial:

- They have specialized tools for precise measurements.

- They know how to handle unexpected issues.

- They can offer valuable advice to improve your project.

Remember, it’s okay to ask for help. Even seasoned builders do it. Better safe than sorry!

In conclusion, measuring and calculating concrete volume doesn’t have to be stressful. Just remember to double-check your data and consider getting professional help when needed. These simple steps can make a big difference in your project’s success. Happy building!

Conclusion And Best Practices

Accurately measuring and calculating concrete volume ensures project success. Follow best practices like using precise measurements and double-checking calculations. This minimizes waste and avoids costly mistakes.

Hey friends, today we’re wrapping up our discussion on how to measure and calculate concrete volume for construction. By following a few simple steps, you can ensure your concrete project runs smoothly. Let’s dive into some concluding thoughts and best practices to keep in mind.Summary Of Key Points

First, let’s recap the main points: – Measure the area: Start by measuring the length, width, and depth of the area where you need concrete. – Use the right formula: For a rectangular area, multiply length x width x depth. For a circular area, use π x radius² x depth. – Convert units if needed: Ensure all measurements are in the same unit, typically cubic meters or cubic feet. – Add extra: Always order about 10% more concrete than you think you need to account for waste and spillage.Recommendations

Here are a few best practices to follow: 1. Double-check measurements: Measure twice to avoid mistakes. Accuracy is key. 2. Consult a professional: If unsure, ask a contractor or an engineer. They can give you peace of mind and ensure you’re on the right track. 3. Use quality materials: Good concrete starts with quality materials. Don’t skimp on this. 4. Prepare the site: Make sure your site is ready before the concrete arrives. This includes setting up forms and reinforcing steel. 5. Plan for weather: Avoid pouring concrete in extreme weather. Too hot or too cold can affect the drying process.Personal Anecdote

I recently asked my friend, who’s a contractor, about a project I was working on. I thought I had everything measured perfectly. But, I had forgotten to account for the slope of my driveway. With his advice, I remeasured and adjusted my calculations. The good news? The project turned out great. In conclusion, taking the time to measure and calculate concrete volume accurately is crucial. It saves time, money, and ensures your project is a success. Follow these best practices and you’ll be well on your way to a solid foundation—literally! Remember, when in doubt, ask a professional. Better safe than sorry. Happy building! “`Frequently Asked Questions

How Do You Calculate The Volume Of Concrete?

Calculate concrete volume by multiplying the length, width, and height of the area. Use the formula: Volume = Length x Width x Height.

How Do I Calculate How Much Concrete I Need?

To calculate concrete needed, measure length, width, and depth of the area in feet. Multiply these dimensions to get cubic feet. Divide cubic feet by 27 to convert to cubic yards. This gives you the amount of concrete required.

How Many Yards Of Concrete Do I Need For A 24x24x4 Slab?

You need 7. 11 cubic yards of concrete for a 24x24x4 slab. Calculate by multiplying length, width, and thickness in feet, then divide by 27.

How Many Bags Of Concrete Do I Need For A 10×10 Slab?

You need about 60 bags of concrete for a 10×10 slab. This is based on an average slab thickness of 4 inches.

Conclusion

Measuring and calculating concrete volume is essential for construction projects. Accurate measurements ensure you mix the right amount of concrete. Use the simple formulas and steps mentioned to avoid errors. Proper preparation saves time and money. It also guarantees the durability of your construction.

Always double-check your calculations for precision. With these tips, you can confidently handle concrete volume measurements. Happy building!

Rakib Sarwar is a seasoned professional blogger, writer, and digital marketer with over 12 years of experience in freelance writing and niche website development on Upwork. In addition to his expertise in content creation and online marketing, Rakib is a registered pharmacist. Currently, he works in the IT Division of Sonali Bank PLC, where he combines his diverse skill set to excel in his career.