Measuring structural loads is vital in engineering projects. It ensures safety and stability.

So, how can you measure these loads accurately? Understanding structural loads is key in any engineering project. Loads affect how structures bear weight and withstand forces. Engineers need to measure these loads to design strong and safe buildings. This process involves analyzing forces that act on a structure, such as weight, wind, and seismic activity.

By calculating these loads, engineers can predict how a structure will perform over time. This helps in preventing failures and ensuring the longevity of the project. In this blog, we will explore the methods to measure structural loads accurately. This knowledge is crucial for anyone involved in engineering and construction.

Credit: www.structure1.com

Introduction To Structural Loads

Hey friends, today we’re diving into something super interesting – structural loads in engineering projects. Ever wondered how buildings stay standing tall, even when faced with strong winds or heavy snow? It’s all about measuring structural loads accurately. Let’s break it down in simple terms.

Importance Of Accurate Measurement

Why does measuring structural loads matter? Well, think of it like this: imagine you are building a bridge. If you don’t know how much weight it can hold, it could collapse. Scary, right? Accurate measurements ensure safety, durability, and longevity of structures. They help engineers design buildings, bridges, and other structures that can withstand various forces.

Here are a few reasons why it’s so important:

- Safety: Prevents accidents and structural failures.

- Cost Efficiency: Avoids overbuilding, saving materials and money.

- Compliance: Meets legal and regulatory standards.

Types Of Structural Loads

Now, let’s talk about the different types of structural loads. These are the forces that buildings and structures need to withstand. Knowing these types helps in designing robust structures. Here are some common ones:

- Dead Loads: These are permanent loads. Think about the weight of the structure itself – walls, floors, roofs.

- Live Loads: These are temporary. Imagine people walking on a floor or furniture placed in a room. These loads can change over time.

- Environmental Loads: These come from nature. Wind, snow, rain – all these can put pressure on structures. For example, a tall building in a windy area needs to handle strong gusts of wind.

- Seismic Loads: These are caused by earthquakes. Buildings in earthquake-prone areas need special designs to stay safe during tremors.

Understanding these loads is like knowing the ingredients in a recipe. Each one plays a crucial role in the final product. And the good news? Once you get the hang of these basics, measuring structural loads becomes much easier.

Basic Concepts

Hey friends, today we’re diving into the basics of measuring structural loads in engineering projects. Imagine you’re building a bridge or a skyscraper. You need to know how much weight each part of the structure can handle. It’s like knowing how much weight a shelf can hold before it breaks. Simple, right? Let’s break it down further with two important ideas: Load Path and Load Distribution.

Load Path

First up, the load path. Think of it like a roadmap. When you place a weight on a structure, the load needs to travel through various parts until it reaches the ground. Imagine you’re standing on the roof of a house. Your weight moves through the roof, down the walls, and finally to the foundation. This journey your weight takes is the load path.

Here’s a simple example to help you understand better:

- Place a book on a table.

- The table legs transfer the weight to the floor.

- The floor transfers the weight to the ground.

Each part of this journey is crucial. If one part fails, the entire structure can be in trouble. So, understanding the load path is essential for ensuring safety.

Load Distribution

Next, let’s talk about load distribution. This is about how the weight is spread out over the structure. Think of a seesaw. If two kids of the same weight sit at each end, the seesaw balances. But if one kid is heavier, the seesaw tips. In the same way, the load needs to be evenly distributed to keep the structure stable.

Here are some key points to remember:

- Uniform Load: Like when you place books evenly on a shelf.

- Point Load: Like hanging a heavy picture frame on one nail.

- Distributed Load: Like spreading sand evenly over a surface.

When designing a structure, engineers aim for balanced load distribution. This prevents any one part from being overloaded. For example, I recently asked an engineer friend about a bridge project. They had to ensure that the weight of vehicles was evenly spread across the bridge. Too much weight in one spot could cause damage.

To sum up, understanding load path and load distribution is like knowing the rules of a game. It helps you play safely and win. If you’re building something, keep these concepts in mind. They’ll guide you in making strong, stable structures.

Tools And Equipment

In engineering projects, measuring structural loads is crucial. It ensures safety and performance. Various tools and equipment help in this process. These tools provide accurate data. They help engineers make informed decisions. Below are some essential tools and equipment used for measuring structural loads.

Strain Gauges

Strain gauges are vital in measuring structural loads. They measure the strain in materials. When a material deforms, strain gauges detect this change. Engineers use this data to assess stress and strain. Strain gauges are small and easy to attach. They provide precise measurements. This makes them ideal for various engineering applications.

Load Cells

Load cells measure force or load. They convert force into an electrical signal. This signal is then read and analyzed. Load cells are highly accurate. They come in different types. These include compression, tension, and shear load cells. Each type serves a specific purpose. Engineers use load cells in testing and monitoring structures. They ensure that structures can handle the loads they are designed for.

Data Collection Methods

Hey there! Measuring structural loads is a crucial part of engineering projects. It’s like knowing how much weight a bridge can hold before it collapses. Different methods are used to gather the necessary data. In this section, we’ll explore the data collection methods. I’ll cover both manual and automated ways. Let’s dive in!

Manual Measurements

Manual measurements involve human effort. Engineers use tools like rulers, tape measures, and scales. It’s like when you measure your room for new furniture. You get precise numbers but it takes time and effort. Here’s how it works:

- Tools: Basic tools like rulers and tape measures are used.

- Process: Engineers measure the structure manually. They record the data on paper or a digital device.

- Accuracy: The accuracy depends on the skill of the person measuring. Mistakes can happen.

I remember when I was in engineering school, we had to measure a small bridge. It took us hours, and we double-checked everything. It was tiring but rewarding when we got the correct data.

Automated Systems

Automated systems use technology to collect data. These systems are faster and often more accurate than manual measurements. Think of it like using a GPS instead of a paper map. Here’s what you need to know:

- Sensors: Devices like strain gauges and load cells are installed on the structure.

- Data Collection: The sensors automatically record data and send it to a computer.

- Software: Specialized software analyzes the data and gives precise results.

For example, in a recent project, we used load cells on a bridge. The sensors worked 24/7, giving us real-time data. It was amazing to see how technology made the job easier and more reliable.

So, whether you’re using manual methods or automated systems, measuring structural loads is essential. Each method has its pros and cons. Choose the one that fits your project best. Happy measuring!

Analyzing Load Data

Hey friends, today we’re diving into the exciting world of structural engineering. Specifically, we’ll talk about how to analyze load data. This is crucial because understanding the loads helps ensure that structures are safe and sturdy. Think of it as the backbone of any engineering project. Ready? Let’s get started!

Data Interpretation

First things first, let’s discuss data interpretation. Imagine you’re a detective, and the load data is your clue. This step is all about making sense of the numbers and figures you have collected.

- Look for patterns

- Identify unusual spikes

- Compare with standard values

For example, if you notice a sudden spike in load data at a certain point, it could indicate an area of potential weakness. Pay attention to these details—they can tell you a lot about the structure’s performance.

Common Analysis Techniques

Now, how do engineers actually analyze this data? There are several techniques that are commonly used:

- Statistical Analysis: This involves using statistical tools to find mean values, variances, and standard deviations. Simple, yet effective.

- Finite Element Analysis (FEA): A bit more complex, FEA uses computer models to simulate how a structure will react under different loads.

- Load Testing: This is the hands-on approach. You physically apply loads to the structure and measure how it behaves.

For instance, I recently asked a colleague to help me with FEA for a bridge project. The results were amazing. We could see how the bridge would perform under different traffic conditions, saving us both time and money.

The good news? These techniques can be applied to almost any engineering project. The key is to choose the right one for your specific needs.

So there you have it! Analyzing load data isn’t as complicated as it sounds. With these basic techniques, you’ll be well on your way to ensuring your structures are both safe and reliable.

Credit: myteamengineering.com

Case Studies

Case studies provide practical insights into how engineers measure structural loads in real-life projects. They showcase the methods and tools used in different scenarios. Understanding these examples helps grasp the principles of load measurement in engineering.

Bridge Load Testing

Bridge load testing involves placing sensors on various parts of the bridge. These sensors measure stress, strain, and displacement. Engineers use the data to assess the bridge’s capacity and safety. For example, in the load testing of a highway bridge, sensors might be placed on the deck, beams, and supports. Trucks with known weights drive across the bridge. The sensors collect data on how the bridge reacts to these loads. This data helps engineers ensure the bridge can handle expected traffic loads.

Building Load Monitoring

Building load monitoring is crucial for high-rise structures. Sensors are installed throughout the building. They track how the structure responds to various loads. These loads include occupancy, wind, and seismic activity. For instance, in a skyscraper project, sensors might be placed on floors, columns, and beams. The data collected helps in understanding how the building behaves under different conditions. This information is vital for maintaining structural integrity and safety over time.

Challenges And Solutions

Hey friends, today we’ll dive into the world of measuring structural loads in engineering projects. Measuring these loads is crucial for ensuring safety and stability. But it’s not always easy. There are a few bumps in the road. However, with the right solutions, these challenges can be managed effectively. Let’s explore some common hurdles and how to overcome them.

Environmental Factors

Environmental factors can be tricky. Think of things like wind, rain, or even temperature changes. These elements can affect measurements and results. For example, strong winds can sway a building, impacting load readings. Rain can add extra weight to structures, altering data.

So, what can we do? Here are some solutions:

- Use Weather-Resistant Equipment: Invest in tools that can withstand harsh weather. This ensures accurate readings no matter the conditions.

- Regular Calibration: Check and adjust your equipment often. This keeps them precise, even in changing weather.

- Protective Measures: Cover sensitive equipment during extreme weather to prevent damage.

Accuracy And Precision

Accuracy and precision are like the backbone of measuring structural loads. Without them, data can be misleading. Imagine you’re baking a cake. If your measurements are off, the cake won’t turn out right. The same goes for structural loads. Incorrect data can lead to unsafe structures.

Here’s how to ensure accuracy and precision:

- High-Quality Instruments: Use top-notch tools for measurements. Cheap tools may save money but can cost accuracy.

- Regular Maintenance: Keep your tools in good shape. Clean and service them regularly.

- Skilled Personnel: Ensure that the people taking measurements are well-trained. Even the best tools need skilled hands.

I recently asked a seasoned engineer about his biggest challenge. He said, “Ensuring precision in every reading is tough, but with the right tools and regular checks, it’s manageable.” This shows that even experts face challenges but find ways to address them.

To sum up, measuring structural loads involves overcoming environmental factors and ensuring accuracy and precision. By using good equipment, maintaining it well, and having skilled personnel, these challenges can be tackled effectively. So, next time you face these bumps, remember, with the right solutions, you can manage them like a pro!

Credit: www.alamy.com

Future Trends

Future trends in measuring structural loads in engineering projects are shaping up to be quite exciting. As technology advances, so does our ability to measure with greater precision and efficiency. Let’s dive into some of the upcoming trends.

Advancements In Technology

Technology is changing fast. In the past, engineers relied heavily on manual tools. Today, high-tech gadgets are taking over. For example, drones are now used to inspect structures. They can fly to hard-to-reach places and take detailed images. This makes it easier and safer to gather data.

Another big change is the use of sensors. These sensors can be placed on buildings, bridges, and other structures. They send real-time data to engineers. This helps them understand how the structure is behaving under different loads. The good news? This data is very accurate.

Lastly, let’s talk about software. New software tools can analyze loads better than before. They use complex algorithms to predict how a structure will react. This helps in making better design decisions.

Improving Measurement Techniques

Measurement techniques are also getting better. One way is through the use of laser scanning. Laser scanners can create detailed 3D models of structures. This helps engineers see any imperfections or weaknesses.

Another method is non-destructive testing. This means checking a structure without causing any damage. For example, ultrasound can be used to check the inside of a concrete wall. It’s like a doctor using an ultrasound to see a baby inside a mother’s womb.

Lastly, the use of artificial intelligence (AI) is becoming more common. AI can analyze vast amounts of data quickly. It can spot patterns and predict issues before they become problems. This is very helpful for engineers.

So, what’s the takeaway? The future of measuring structural loads is bright. With new technology and better techniques, engineers can create safer and more efficient structures. And that benefits everyone.

Frequently Asked Questions

What Are The Four Types Of Structural Loads?

The four types of structural loads are dead loads, live loads, wind loads, and seismic loads. Dead loads are static forces, live loads are dynamic forces, wind loads are caused by wind pressure, and seismic loads result from earthquakes. These loads impact structural integrity and safety.

How To Calculate The Load Bearing Capacity Of A Structure?

Calculate load-bearing capacity by assessing material strength, structural design, and safety factors. Consult engineering standards and use appropriate software tools.

What Is Load Measured In Engineering?

Load in engineering refers to the force or weight supported by a structure or component. It includes static and dynamic forces.

What Is The Formula For Calculating Load?

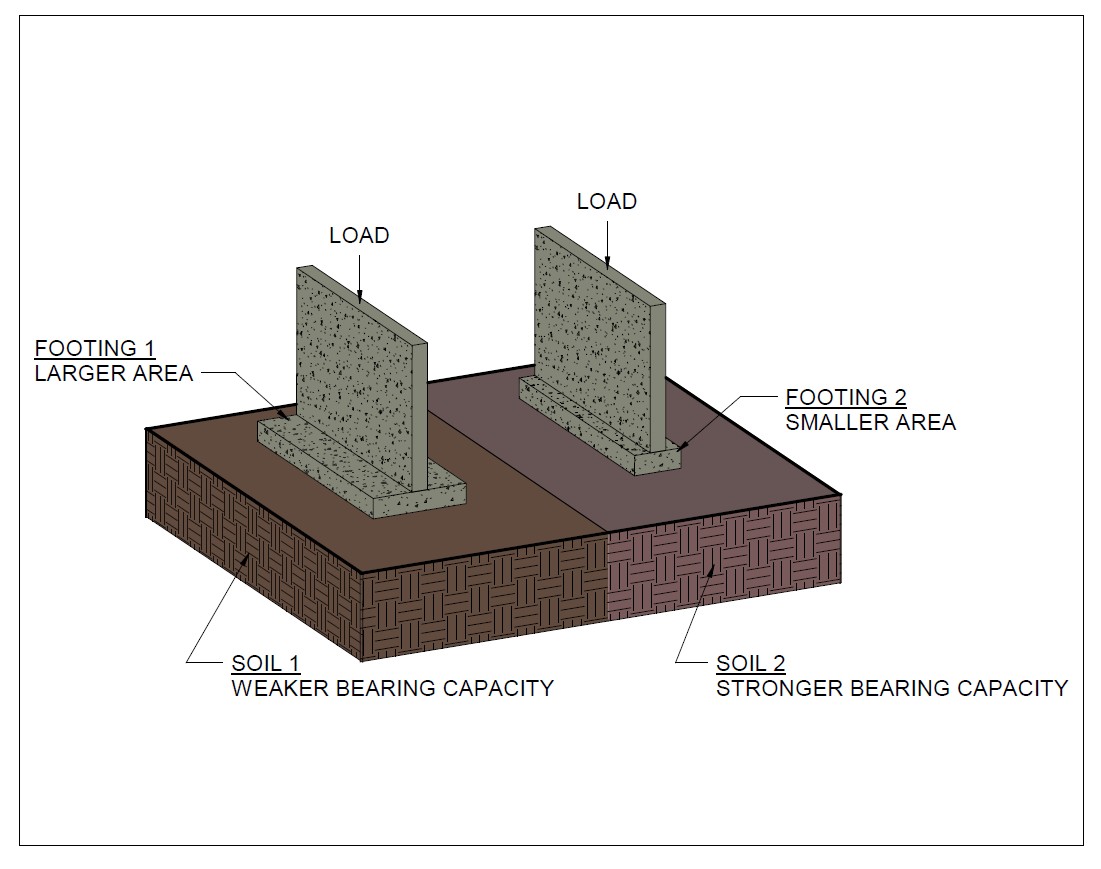

The formula for calculating load is Load (P) = Force (F) / Area (A). This measures stress on a material.

Conclusion

Measuring structural loads is crucial in engineering projects. It ensures safety and durability. Follow the right methods and tools for accurate results. Keep learning and stay updated with new techniques. This knowledge can help you avoid costly mistakes. Structural load measurements are essential for every engineer.

Stay diligent, and your projects will succeed.

Rakib Sarwar is a seasoned professional blogger, writer, and digital marketer with over 12 years of experience in freelance writing and niche website development on Upwork. In addition to his expertise in content creation and online marketing, Rakib is a registered pharmacist. Currently, he works in the IT Division of Sonali Bank PLC, where he combines his diverse skill set to excel in his career.