In engineering, accurate measurements are critical. Laser scanning and traditional methods are both popular.

Understanding how these methods compare can help in choosing the right one for your project. Laser scanning uses advanced technology to capture detailed data quickly. Traditional methods rely on manual tools and techniques developed over many years. Each has its strengths and weaknesses.

This blog will explore the differences between laser scanning and traditional measurement methods. You will learn about their pros and cons, and how they fit into modern engineering. Whether you’re an engineer, a student, or just curious, this comparison will provide valuable insights. Let’s dive into the details and see which method suits your needs best.

Credit: www.mdpi.com

Laser Scanning Technology

Laser scanning technology is transforming how engineers measure and map structures. Unlike traditional methods that can be slow and labor-intensive, laser scanning offers a faster and more accurate alternative. Let’s dive into how this technology works and its key features.

How Laser Scanning Works

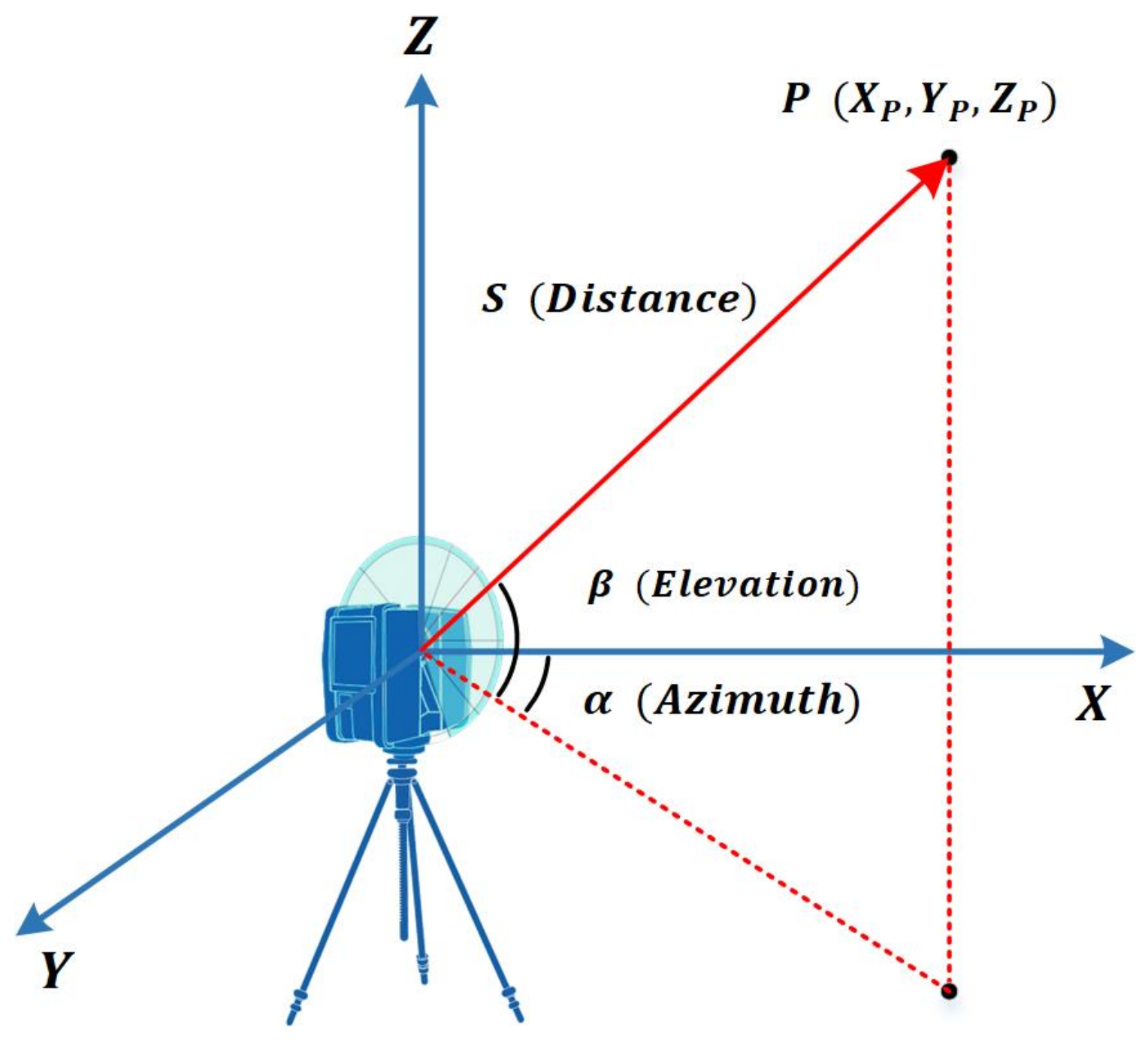

Laser scanning uses light to measure distances. Think of it like how bats use sound waves to navigate, but with lasers. A laser scanner sends out a beam of light and measures how long it takes for the light to bounce back. This process is called “time-of-flight.” The scanner repeats this process thousands of times per second, creating a detailed 3D map of the area.

This method is quick and provides a wealth of data. Imagine trying to measure every corner of a building with a tape measure. It would take forever! Laser scanning does this in minutes, and with much more detail.

Key Features Of Laser Scanning

Laser scanning comes with several impressive features that set it apart from traditional methods.

- High Accuracy: Laser scanners can measure with millimeter precision. This level of detail is crucial for engineering projects.

- Speed: Traditional methods can take days or even weeks. Laser scanning can complete the same task in hours.

- Comprehensive Data: The scanner captures millions of data points. This creates a complete and detailed 3D model.

- Safety: Scanners can reach areas that might be dangerous for humans. This reduces the risk of accidents.

Here’s a quick comparison to illustrate these points:

| Feature | Laser Scanning | Traditional Methods |

|---|---|---|

| Accuracy | High (millimeters) | Moderate (centimeters) |

| Speed | Fast (hours) | Slow (days/weeks) |

| Data | Comprehensive (millions of points) | Limited (hundreds of points) |

| Safety | High (remote operation) | Moderate (manual operation) |

In conclusion, laser scanning technology is a powerful tool in engineering. It offers high accuracy, speed, and safety. And the detailed data it provides is invaluable for creating precise 3D models. So, if you’re still using traditional methods, it might be time to consider laser scanning.

Credit: www.instagram.com

Traditional Measurement Methods

Traditional measurement methods have been the backbone of engineering for many years. These methods involve manual techniques and tools that engineers have relied on for accuracy and precision. While newer technologies are emerging, traditional methods still hold value in various engineering applications.

Common Traditional Techniques

Several traditional techniques are used to measure distances and dimensions. Hand measurements, using rulers and tapes, are common. Engineers often apply triangulation, a method that involves creating triangles to determine distances. Leveling is another key technique, ensuring surfaces are even and structures are properly aligned. These methods require skill and experience to achieve accurate results.

Tools Used In Traditional Methods

Various tools support traditional measurement techniques in engineering. The tape measure is a staple for quick and easy measurements. Calipers, both vernier and digital, offer precise readings of small dimensions. Levels, such as spirit levels, help ensure surfaces are flat. Theodolites and total stations provide more advanced measurement capabilities, essential for larger projects. Engineers use these tools to gather data manually, ensuring each measurement is carefully verified.

Accuracy And Precision

Accuracy and precision are vital in engineering measurements. They determine the success of a project. Traditional methods and laser scanning offer different levels of both.

Comparing Accuracy Levels

Laser scanning provides higher accuracy compared to traditional methods. This technology captures more data points. Each point represents a precise measurement. Traditional methods rely on manual tools. This often leads to errors. Human error is a common issue. Laser scanning eliminates this problem.

Precision In Different Scenarios

Laser scanning excels in complex environments. It captures details in hard-to-reach areas. Traditional methods struggle in such scenarios. They require more time and effort. Precision is crucial in large-scale projects. Laser scanning ensures consistent results. Traditional methods can vary in precision. This depends on the skill of the operator.

Time And Efficiency

Time and efficiency are critical in engineering projects. Engineers often face strict deadlines. Choosing the right measurement method can save time. It can also improve project efficiency.

Speed Of Data Collection

Laser scanning collects data quickly. It captures millions of points in seconds. This creates a detailed 3D model. Traditional methods are slower. They require manual measurements. This takes much longer. Engineers must move tools and record data by hand.

Time-consuming Aspects

Traditional measurement methods involve several steps. Each step adds time. Setting up tools, taking measurements, and recording data take hours. Errors can occur. Fixing these errors takes more time.

Laser scanning reduces these time-consuming tasks. The scanner captures data in one go. It reduces the need for manual work. Engineers can focus on analyzing the data. This improves overall efficiency.

Cost Implications

Understanding the cost implications of laser scanning and traditional measurement methods in engineering is crucial. Both methods have different cost structures that can impact a project’s budget significantly. Let’s break down the costs associated with each method under key headings.

Initial Investment Costs

Laser scanning technology requires significant initial investment. The equipment itself can be expensive. Training staff to use the technology adds to the cost. Traditional measurement methods, such as manual surveying, involve lower initial costs. The tools required are cheaper. Training costs are also lower. However, the time required for manual measurements can add up quickly.

Long-term Cost Benefits

Laser scanning offers substantial long-term cost benefits. The technology reduces the time needed for measurements. It also minimizes human errors. This saves money on rework and corrections. Traditional methods may seem cheaper initially. But they often result in higher long-term costs. The time-intensive nature of manual measurements can delay projects. This leads to increased labor costs and potential project overruns.

Applications In Engineering

Hey friends, today we’re diving into the world of engineering. Specifically, we’ll look at how Laser Scanning compares to Traditional Measurement Methods. These methods are used in various engineering applications. Whether it’s building bridges or designing car parts, accurate measurements are crucial. Let’s explore some common applications.

Infrastructure Projects

First, let’s talk about infrastructure projects. Think about roads, bridges, and buildings. These structures need to be precise. Traditional methods often use tape measures and levels. But, laser scanning offers a faster and more accurate alternative.

- Speed: Laser scanning can capture a lot of data quickly. Traditional methods are slower.

- Accuracy: Laser scans are highly accurate. This reduces errors in construction.

- Data: You get a 3D model with laser scanning. Traditional methods give you 2D plans.

Imagine you’re building a bridge. With traditional methods, you measure manually. This takes time and can lead to mistakes. But with laser scanning? You get detailed 3D models. It’s like having a digital blueprint. And this helps in making better decisions.

Mechanical Engineering

Now, let’s move on to mechanical engineering. This field deals with designing machines and tools. Here, precision is everything. Traditional methods use tools like calipers and micrometers. While these are good, laser scanning offers some unique benefits.

- Complex Shapes: Laser scanning easily measures complex shapes. Traditional tools struggle here.

- Reverse Engineering: Need to recreate a part? Laser scanning makes it easy. Traditional methods are more complicated.

- Prototyping: Laser scans speed up the prototyping process. Traditional methods can slow you down.

Let’s say you’re designing a new car engine. Traditional tools might miss small details. But laser scanning catches everything. It’s like using a magnifying glass. You see all the little parts clearly. This ensures your design is spot-on. And that means fewer problems later on.

So, whether it’s building bridges or designing engines, laser scanning has its perks. It’s faster, more accurate, and gives you better data. But traditional methods have their place too. They’re tried and true. And sometimes, simpler tools are just what you need.

In the end, it’s about choosing the right tool for the job. What do you think? Which method would you prefer for your projects? Share your thoughts below!

Pros And Cons

Comparing laser scanning and traditional measurement methods in engineering is essential. Each method has its own strengths and weaknesses. This section explores the pros and cons of both approaches.

Advantages Of Laser Scanning

Laser scanning provides high accuracy and precision. It captures millions of data points quickly. This method is non-contact, which means no physical interaction with the object. It creates detailed 3D models, which are useful for complex structures. Laser scanning also saves time, as it can cover large areas swiftly.

Advantages Of Traditional Methods

Traditional methods are well-established and widely understood. They require simple tools, like tape measures and calipers. These tools are affordable and easy to use. Traditional methods are also reliable for smaller projects. They do not require advanced technology or software, making them accessible.

Limitations Of Both Methods

Laser scanning can be expensive. It requires specialized equipment and trained operators. The data files are large and need powerful computers for processing. Traditional methods, on the other hand, can be time-consuming. They may lack precision for complex or large-scale projects. Human error is also a potential issue with traditional methods.

Credit: leica-geosystems.com

Future Trends

As technology advances, the engineering sector witnesses a shift in how measurements are taken. Laser scanning and traditional measurement methods are at the forefront of this evolution. Understanding the future trends in this area helps professionals stay ahead in their field.

Technological Advancements

Laser scanning technology is becoming more advanced. Devices are now smaller, faster, and more accurate. These scanners can capture vast amounts of data in a short time. This results in precise 3D models. The software used to process this data is also improving. It allows for better analysis and visualization of the scanned objects.

Traditional measurement methods are not left behind. Tools such as calipers and micrometers are also evolving. They are becoming more digital. This digital transformation helps in reducing human error. It also makes data recording more efficient.

Potential Industry Shifts

The engineering industry is likely to see a shift towards more digital methods. As laser scanning becomes more affordable, more companies will adopt it. This will lead to a decrease in the use of traditional measurement tools.

Industries such as construction and manufacturing will benefit greatly. Laser scanning provides a level of detail that traditional methods cannot match. This will result in better project planning and execution. It will also help in maintaining quality control.

The future trends in measurement methods show a clear move towards digitalization. This shift will enhance accuracy and efficiency in engineering projects.

Frequently Asked Questions

What Is The Difference Between A Survey And A Laser Scan?

A survey measures specific points and distances using traditional tools. A laser scan captures detailed, 3D images of environments.

What Are The Cons Of Laser Scanning?

Laser scanning can be expensive. It requires specialized equipment and skilled operators. It may struggle with reflective or transparent surfaces. Data processing can be time-consuming.

What Is The Difference Between Structured Light Scanning And Laser Scanning?

Structured light scanning projects a pattern onto an object, capturing distortions to create 3D models. Laser scanning uses a laser beam to measure distances, creating precise 3D maps.

How Accurate Is Laser Scanning?

Laser scanning accuracy ranges from 1mm to 10mm, depending on the equipment and conditions. High precision is achievable.

Conclusion

Laser scanning offers precision and speed. Traditional methods provide tried-and-true reliability. Engineers can choose based on project needs. Each method has unique advantages. Laser scanning is great for complex details. Traditional methods work well for simpler tasks. Both have a place in engineering.

The right choice depends on specific requirements. Evaluate your project’s demands. Then decide the best measurement method.

Rakib Sarwar is a seasoned professional blogger, writer, and digital marketer with over 12 years of experience in freelance writing and niche website development on Upwork. In addition to his expertise in content creation and online marketing, Rakib is a registered pharmacist. Currently, he works in the IT Division of Sonali Bank PLC, where he combines his diverse skill set to excel in his career.