Thermal expansion occurs when materials change size due to temperature shifts. It’s a crucial concept in engineering that affects design and safety.

In the realm of engineering, understanding thermal expansion measurements can mean the difference between a successful project and a structural failure. Materials expand and contract with temperature changes, influencing everything from bridges to electronic circuits. Ignoring these changes can lead to cracks, warping, or even catastrophic failures.

By grasping the principles of thermal expansion, engineers can predict how materials will behave under different temperatures. This knowledge allows for better design decisions, ensuring durability and functionality. Join us as we delve into the intricacies of thermal expansion measurements, providing insights that are vital for safe and effective engineering solutions.

Thermal Expansion Basics

Hey friends, today we’re diving into the world of thermal expansion. Ever noticed how a metal bridge has gaps? Or why railway tracks have small spaces between them? That’s because of thermal expansion. When materials heat up, they expand. When they cool down, they shrink. Simple, right? Let’s break it down even further.

Definition And Importance

Thermal expansion is when a material changes its size or volume because of temperature changes. Imagine blowing up a balloon. As you add air, it gets bigger. Similarly, when you heat a material, its particles move more and it expands.

Why is this important in engineering? Well, if we don’t account for these changes, structures can break or malfunction. Think about bridges, buildings, or even simple metal rods. If they expand too much without space to move, they can bend or crack.

Types Of Thermal Expansion

There are three main types of thermal expansion:

- Linear Expansion: This is when a material grows longer. Imagine a metal rod getting heated and becoming slightly longer.

- Area Expansion: Here, the surface area of a material increases. Think of a flat metal sheet expanding in all directions.

- Volume Expansion: This is the overall increase in the size of a material. Picture a cube of metal expanding in all three dimensions.

Each type matters in different engineering scenarios. For example, linear expansion is crucial for long structures like bridges. Volume expansion is essential in tanks and containers.

Understanding these types helps engineers design better, safer structures. They can predict how much space to leave for expansion and choose the right materials.

So next time you see a gap in a bridge or the spaces between railway tracks, you’ll know why they’re there. It’s all about keeping things safe and functional, even when the temperature changes.

Got questions about thermal expansion? Drop them in the comments below!

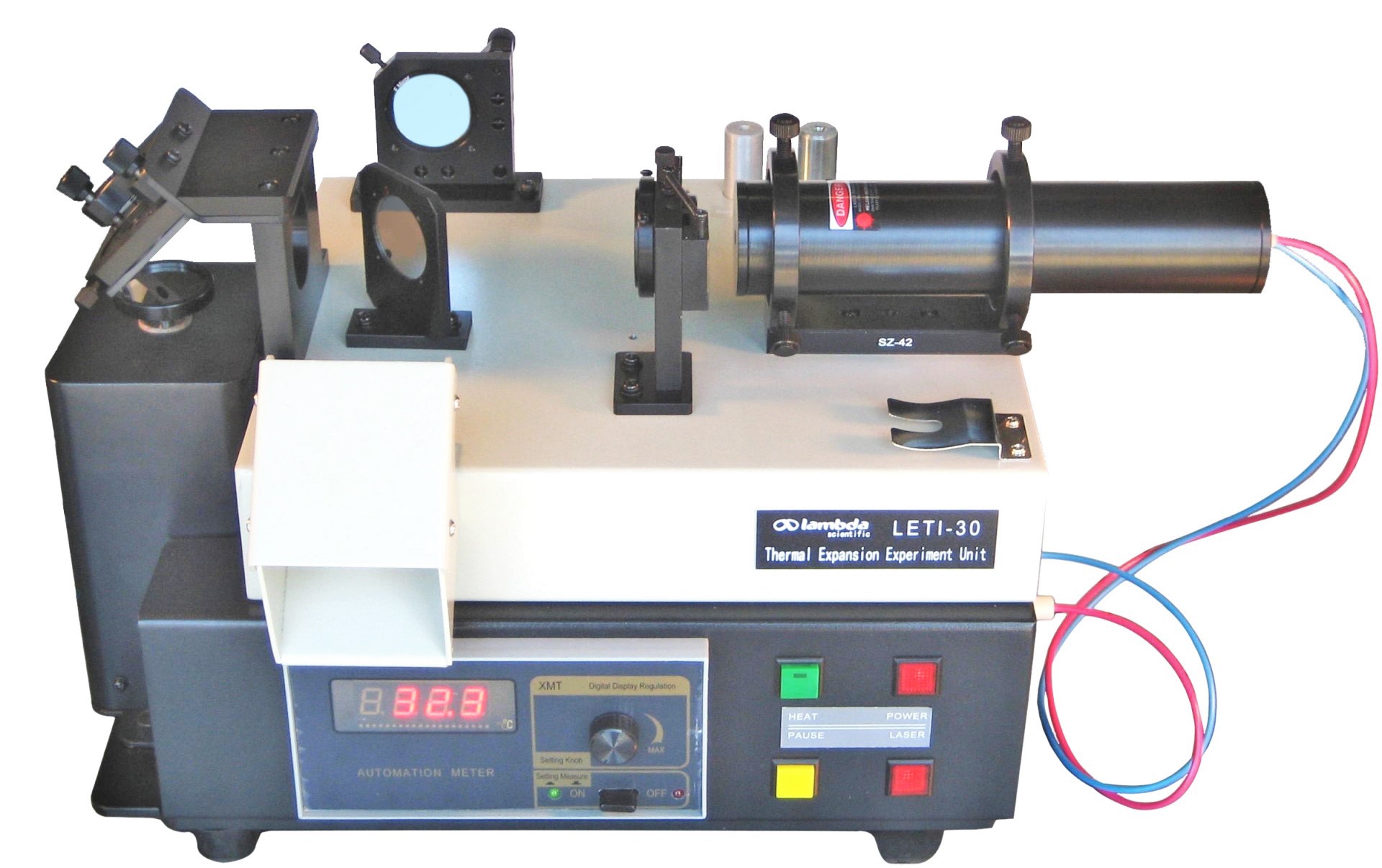

Credit: lambdasys.com

Materials And Thermal Expansion

In engineering, understanding thermal expansion is crucial. Different materials expand or contract with temperature changes. This can affect the design and functionality of structures and components. Knowing how materials behave under thermal stress helps in creating safe and efficient products.

Coefficient Of Expansion

The coefficient of expansion measures how much a material expands per degree of temperature change. It is essential to consider this factor during the design process. A high coefficient means the material will expand more with heat. Engineers must calculate these changes to avoid structural failures.

Material Properties

Each material has unique properties that determine its response to temperature changes. Metals, for instance, usually have higher expansion coefficients compared to ceramics. Plastic materials may behave differently than metals. Understanding these properties helps in selecting the right material for specific applications.

Material properties like thermal conductivity, tensile strength, and elasticity also play a role. They affect how a material expands or contracts. Engineers must consider all these factors to ensure the durability and stability of their designs.

Measurement Techniques

Understanding thermal expansion is crucial in engineering. Different materials expand or contract with temperature changes. Engineers use specific techniques to measure this expansion. These techniques can be divided into two main categories: contact methods and non-contact methods.

Contact Methods

Contact methods involve direct interaction with the material. One popular technique is the use of dial indicators. These devices measure changes in length with high precision. Engineers place the material between two fixed points. As the material expands, the dial indicator records the change.

Another common method is using strain gauges. These small sensors attach directly to the material’s surface. When the material expands, the strain gauge stretches. This stretch changes the electrical resistance. The change in resistance provides data on the material’s expansion.

Non-contact Methods

Non-contact methods do not touch the material. One example is laser interferometry. This technique uses laser beams to measure changes in distance. Engineers aim the laser at the material. As the material expands, the laser beam’s path changes. These changes provide precise measurements.

Another non-contact method is digital image correlation. Engineers use cameras to capture images of the material. They analyze these images to detect changes. This method provides detailed data on how the material deforms.

Each measurement technique has its advantages. Choosing the right one depends on the material and the precision needed. Understanding these methods helps engineers make better decisions. Accurate measurements ensure safety and efficiency in engineering projects.

Instruments Used

Hey friends, today we’re diving into the world of thermal expansion measurements in engineering. Let’s focus on the instruments used for these measurements. These tools are essential for engineers to determine how materials expand or contract with temperature changes. Let’s break it down to keep things simple and easy to understand.

Interferometers

Interferometers are precise instruments. They measure tiny changes in length. How? By using light waves. It’s like using a ruler, but much more accurate.

Here’s how it works:

- Light waves pass through the material.

- The waves reflect back.

- The device measures the change in the light wave.

Simple, right? Well, it’s a bit more complex in practice, but the idea is straightforward. I remember the first time I saw an interferometer in action. It was like magic. The precision was incredible!

Dilatometers

Dilatometers are another tool engineers use. They measure how much a material changes in volume with temperature changes. Imagine a balloon. When you heat it, it expands. Dilatometers measure that expansion, but in solids.

There are different types of dilatometers:

- Push-rod dilatometers

- Capacitance dilatometers

Push-rod dilatometers are common. They use a rod to measure the material’s expansion directly. Capacitance dilatometers measure changes in electrical capacity. Both are accurate and useful in different situations.

One time, I had to measure the expansion of a new alloy. Using a dilatometer made the job easy. I could see the changes clearly and make the necessary adjustments to my project.

So, that’s a quick look at two key instruments used in thermal expansion measurements. Interferometers and dilatometers each have their place in an engineer’s toolkit. They help us understand and predict how materials behave with temperature changes. Pretty cool, huh?

Calibration Procedures

Understanding thermal expansion is crucial in engineering. Accurate measurements are essential for success. Calibration procedures ensure these measurements are reliable. This section will guide you through the necessary steps.

Standard Materials

Using standard materials is important for calibration. These materials have known thermal expansion properties. Common choices include metals like aluminum and steel. They provide a reliable reference point for measurements.

Calibration Steps

First, select the standard material for calibration. Ensure it is clean and free of defects. Place it in a controlled environment. The temperature must be consistent. This step guarantees accurate results.

Next, measure the initial dimensions of the material. Use precise tools like calipers. Record these measurements carefully. They serve as the baseline for comparison.

Gradually increase the temperature of the material. Use a calibrated heating device. Monitor the temperature closely. Consistency is key to accurate calibration.

As the temperature rises, measure the material’s dimensions at set intervals. Record these measurements accurately. Compare them to the initial dimensions. This comparison reveals the thermal expansion characteristics.

Finally, analyze the data. Use it to calibrate your instruments. Accurate data ensures reliable thermal expansion measurements in future projects.

Credit: en.wikipedia.org

Data Interpretation

Data interpretation in thermal expansion measurements is vital. Engineers need accurate results to ensure safety and efficiency. Properly analyzing data helps in understanding material behavior under varying temperatures. This section covers key aspects of data interpretation, including analyzing results and identifying common errors.

Analyzing Results

Analyzing thermal expansion results requires attention to detail. Engineers compare measured values with theoretical predictions. This helps in validating the accuracy of the measurements. Any discrepancies might indicate measurement errors or material anomalies.

Graphs and charts play a crucial role. They provide a visual representation of data. Engineers look for consistent patterns. Sudden spikes or drops might signal issues. Comparing data over time helps in spotting trends. This information is critical for making informed decisions.

Common Errors

Common errors can affect data accuracy in thermal expansion measurements. Calibration errors are frequent. Instruments must be calibrated regularly. Improper calibration leads to incorrect readings. Environmental factors also impact measurements. Temperature fluctuations can alter results. Engineers must control the testing environment.

Human errors are another concern. Incorrect data entry or misinterpretation can skew results. Double-checking data entries helps in minimizing these errors. Training engineers in proper measurement techniques is crucial. This ensures consistent and accurate data collection.

Applications In Engineering

Understanding thermal expansion measurements is crucial in engineering. Different applications rely on accurate data to ensure safety and functionality. Engineers use thermal expansion data in various fields.

Construction Materials

Thermal expansion affects buildings and structures. Construction materials expand and contract with temperature changes. Engineers must consider this to prevent structural damage. For instance, bridges use expansion joints. These joints allow for movement without causing cracks.

Concrete, steel, and glass all expand differently. Engineers must select materials carefully. They need to match the thermal properties to the environment. This ensures the structure remains safe and durable.

Aerospace Components

Aerospace components face extreme temperatures. Thermal expansion data is vital here. Spacecraft materials expand and contract in space. Engineers design components to withstand these changes. This ensures that the spacecraft functions properly.

Jet engines also experience temperature fluctuations. Materials must endure high heat without deforming. Engineers use thermal expansion data to select the right alloys. This keeps the engines running efficiently and safely.

Credit: study.com

Future Developments

Future developments in thermal expansion measurements hold exciting prospects. Engineers continue to seek better accuracy and efficiency. As technology advances, new methods and materials emerge. These innovations promise to enhance thermal expansion measurements.

Advanced Materials

Advanced materials play a crucial role in future thermal expansion measurements. Researchers are developing materials with high stability. These materials can withstand extreme temperatures. They help in providing precise measurements. Engineers are exploring nanomaterials for their unique properties. These tiny materials offer greater control over thermal expansion.

Innovative Techniques

Innovative techniques are transforming how engineers measure thermal expansion. Laser-based methods provide high precision. They allow for real-time monitoring of changes. Digital image correlation techniques are gaining popularity. They offer non-contact, accurate measurements. Engineers also use advanced computational models. These models predict thermal expansion with higher accuracy.

Frequently Asked Questions

How Is Thermal Expansion Measured?

Thermal expansion is measured using a dilatometer. This device accurately detects changes in an object’s dimensions due to temperature variations.

How Is Thermal Expansion Used In Engineering?

Thermal expansion is used in engineering to design bridges, railways, and pipelines. It ensures structures accommodate temperature changes.

How Do You Calculate Thermal Expansion?

Calculate thermal expansion using the formula: ΔL = αLΔT. Here, ΔL is the change in length, α is the coefficient of thermal expansion, L is the original length, and ΔT is the temperature change.

What Do You Understand By Thermal Expansion Of?

Thermal expansion refers to the increase in a material’s volume due to a rise in temperature. This occurs because particles move more and take up more space. Different materials expand at different rates.

Conclusion

Understanding thermal expansion is crucial in engineering. It helps in design accuracy. Engineers use this knowledge to prevent material failure. Thermal expansion data ensures safety and durability. It aids in creating reliable structures and systems. By measuring thermal expansion, engineers make informed decisions.

This understanding leads to better performance of materials. It also enhances the lifespan of engineering projects. In essence, mastering thermal expansion measurements is key. It ensures the success of engineering endeavors.