The angle of repose is a key concept in physics and engineering. It is the steepest angle at which a pile of material remains stable.

Understanding the angle of repose is crucial for industries dealing with bulk materials. This angle helps in designing equipment and storage solutions. It applies to grains, sand, gravel, and many other substances. Measuring the angle of repose ensures safety and efficiency in handling materials.

In this blog post, we will explore what the angle of repose is and how it is measured. You’ll learn about its importance in various industries and the methods used to determine it. Stay tuned to gain insights into this fascinating topic.

Angle Of Repose Basics

Hey friends, today we’re diving into a fascinating topic: the angle of repose. It’s more interesting than it sounds, I promise! This concept is crucial in many industries, and understanding it can help you grasp how materials behave. So, let’s break it down in simple terms.

Definition

The angle of repose is the steepest angle at which a pile of material remains stable. Imagine you have a pile of sand. If you add more sand, at some point, it starts to slide down. The angle at which the sand stops sliding and forms a stable slope is the angle of repose.

Here’s a quick example. Think about how sugar forms a little mound when you pour it. The slope of that mound is the angle of repose. It’s measured in degrees, like 30° or 45°.

Importance In Industry

Why should we care about the angle of repose? Good question! It plays a big role in various industries. Let’s look at a few:

- Construction: Builders need to know how sand, gravel, and other materials will behave when piled up.

- Pharmaceuticals: For making pills, it’s crucial to understand how powders will flow and settle.

- Agriculture: Farmers store grains in silos, and knowing the angle of repose helps in designing these storage spaces.

In short, if you work with materials that pile up, the angle of repose is something you can’t ignore. It helps in designing equipment and storage solutions, ensuring safety and efficiency.

How Is It Measured?

Measuring the angle of repose is pretty straightforward. You can do it in a few steps:

- Pour the material into a pile.

- Measure the height of the pile.

- Measure the radius of the base of the pile.

- Use these measurements to calculate the angle with a simple formula: tan(θ) = height / radius.

And there you have it! A quick and easy way to find out the angle of repose. This measurement can then guide you in various tasks and projects.

So, the next time you see a pile of anything, you’ll know there’s some science behind how it sits. Pretty cool, right?

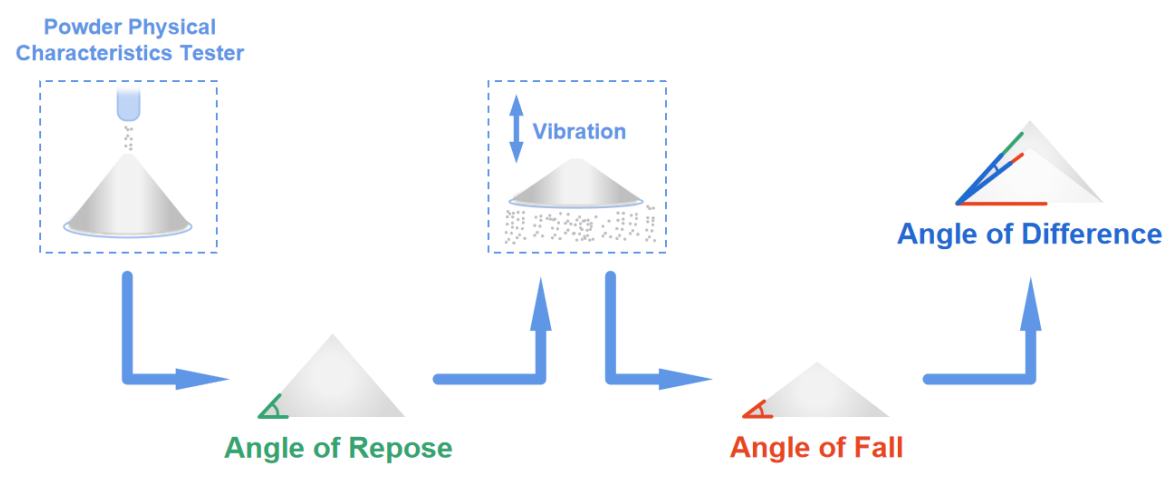

Credit: www.bettersizeinstruments.com

Factors Influencing Angle

The angle of repose is the steepest angle at which loose material remains stable. Several factors influence this angle. Understanding these factors helps in various industries. From construction to agriculture, knowing the angle of repose is crucial.

Material Properties

Material properties play a significant role in determining the angle of repose. The size, shape, and texture of the particles affect stability. Larger particles tend to have a higher angle of repose. Rounded particles slip more easily than angular ones.

Moisture content also impacts the angle. Wet materials may clump together, increasing the angle. Dry materials might form a lower angle. Cohesion between particles is another important factor. Higher cohesion results in a higher angle of repose.

Environmental Conditions

Environmental conditions are crucial in measuring the angle of repose. Temperature can affect particle behavior. High temperatures may dry out materials, altering their angle.

Humidity levels also play a role. High humidity can increase moisture content, changing the angle. Wind conditions impact how materials settle. Strong winds can flatten the pile, reducing the angle of repose.

Understanding these factors is essential. It ensures accurate measurement and application in real-world scenarios.

Measurement Techniques

The angle of repose is a key concept in materials science. It is crucial for understanding how materials pile up. Measuring this angle involves various techniques. These techniques are divided into direct and indirect methods. Let’s explore these in detail.

Direct Methods

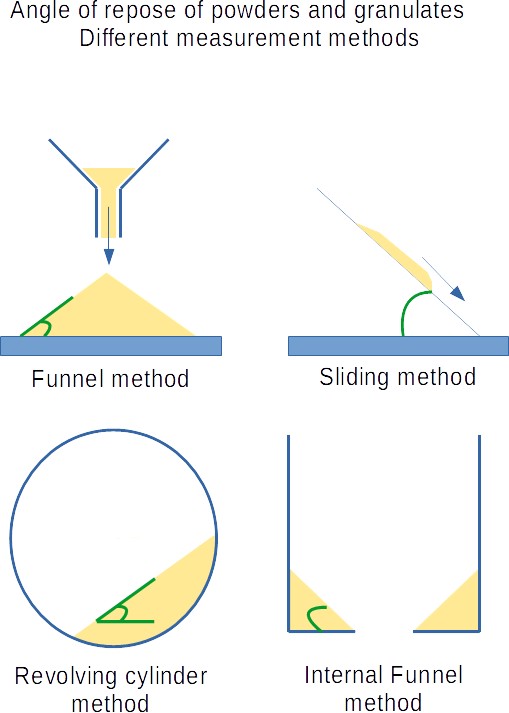

Direct methods involve physical measurement. One common technique is the fixed funnel method. The material flows through a funnel. It forms a cone-shaped pile. The angle at the base of this cone is measured. This angle is the angle of repose.

Another direct method is the tilting box method. A box filled with the material is tilted. The angle at which the material begins to slide is recorded. This angle is also the angle of repose.

Indirect Methods

Indirect methods use mathematical models and simulations. One technique involves image analysis. Pictures of the material pile are taken. Software calculates the angle of repose from these images.

Another indirect method is using digital modeling. Computer programs simulate the material flow. These simulations predict the angle of repose. These methods are useful for complex materials.

Equipment Used

The angle of repose is an important concept in material science. It measures the steepest angle at which a material remains stable. To measure this angle accurately, specific equipment is necessary.

Protractors And Scales

Protractors are simple tools used to measure angles. They are essential for determining the angle of repose. A protractor is placed at the base of the material pile. This helps in measuring the angle between the base and the slope of the pile.

Scales are used to ensure the material pile is uniform. They help in measuring the height and base of the pile. This data is crucial for accurate angle calculation.

Advanced Instruments

Advanced instruments provide more precise measurements. A tilting box apparatus is one such instrument. It involves a box with adjustable angles. The material is placed inside, and the box is tilted until the material starts to slide.

Another advanced tool is the fixed funnel method. Here, material flows through a funnel onto a flat surface. The angle of repose is calculated by measuring the height and radius of the resulting pile. High-tech devices, like laser scanners, can also be used. They offer precise measurements and 3D models of the material pile.

Practical Applications

The angle of repose is crucial in various industries. It determines how materials behave when piled. Practical applications of the angle of repose are vast. Let’s explore some key areas:

Construction

In construction, the angle of repose helps in designing slopes. It ensures stability in earthworks like embankments. Engineers use it to predict the behavior of soils and sands. Proper slope design prevents landslides. It also aids in planning the storage of construction materials. Piles of sand or gravel need careful management. The angle of repose guides safe and efficient stacking.

Pharmaceuticals

The pharmaceutical industry relies on the angle of repose. It affects the handling of powders and granules. Smooth flow is essential in tablet making. The angle of repose helps in predicting flow characteristics. It ensures uniform mixing of ingredients. This leads to consistent dosage in tablets. Proper measurement prevents issues in production. It enhances the quality and safety of medicines.

Credit: powderprocess.net

Challenges In Measurement

Hey friends, today we’re diving into something quite interesting – the challenges in measuring the angle of repose. This angle is important in many industries, like construction and agriculture. But measuring it isn’t always a walk in the park. Let’s break it down and understand the hurdles we face.

Accuracy Issues

One of the biggest problems? Accuracy. When you’re dealing with loose materials like sand or grains, getting a precise measurement can be tricky. The particles might not settle the same way each time. This can lead to different readings. Imagine trying to measure how high you jump. But each time you jump, you land differently. Hard to get the same number every time, right?

Accuracy issues often arise from:

- Different particle sizes

- Moisture content

- Shape of the particles

Each of these factors can change how the material settles. It’s like trying to stack different shaped blocks. Some will stack neatly, others won’t.

Environmental Variability

Another challenge is the environment. Where you measure can change the result. For example, wind can blow particles around. Temperature can make them expand or contract. Even the surface where you measure matters. A smooth surface gives different results than a rough one.

Here’s how the environment can mess with your measurements:

- Wind: Moves particles around, making them settle differently.

- Temperature: Affects particle size and how they stick together.

- Surface Texture: Smooth or rough surfaces impact how particles pile up.

Think about it this way. It’s like trying to measure water in a cup during a storm. The wind and rain make it nearly impossible to get an accurate reading.

So, what’s the takeaway? Measuring the angle of repose is more than just a simple task. It involves understanding and dealing with these accuracy and environmental challenges. And that’s what makes it so fascinating!

Improving Measurement Accuracy

When measuring the angle of repose, accuracy is critical. Small errors can lead to big problems, especially in industries like construction or agriculture. So, how can you make sure your measurements are spot-on? Let’s break it down, step by step.

Calibrating Equipment

First things first, let’s talk about equipment. If your tools aren’t calibrated, your measurements will be off. It’s like trying to bake a cake with a broken oven. You won’t get the results you want.

Here’s what you need to do:

- Check the Manufacturer’s Manual: Always follow the instructions. They know their equipment best.

- Use Calibration Weights: These weights help ensure your scales are accurate. Think of them as a benchmark.

- Regularly Recalibrate: Over time, equipment can drift out of calibration. Recalibrate often to keep things precise.

Personal tip: I once skipped recalibrating my scale. The result? A project delayed by two weeks. Not fun.

Standard Procedures

Next, let’s look at procedures. Following standard methods can make a huge difference. It’s like following a recipe. If you skip steps, you’ll end up with a mess.

Here’s a simple process to follow:

- Prepare Your Material: Make sure it’s dry and free from lumps. Wet or clumpy material can skew results.

- Set Up Your Equipment: Place your material in the funnel or hopper. Ensure it’s at the correct height.

- Allow Material to Flow: Let it flow naturally to form a pile. Don’t interfere. Just let gravity do its job.

- Measure the Angle: Use a protractor or digital angle finder. Make sure to measure from the base to the peak.

This method works. Trust me. I’ve used it in countless projects, and it never fails.

So, there you have it. By calibrating your equipment and following standard procedures, you can improve your measurement accuracy. And that means better results for your projects. Simple, right?

Expert Tips

Understanding the angle of repose can be tricky. But don’t worry! We’re here to make it simple. In this section, we’ll share some expert tips to help you measure the angle of repose accurately. Whether you’re a student or a professional, these tips will come in handy.

Best Practices

Measuring the angle of repose isn’t rocket science. But it does require some attention to detail. Here are some best practices to follow:

- Use a clean and dry surface: Ensure the surface you are using is free from debris and moisture. This helps in getting an accurate measurement.

- Consistent material: Use the same type and amount of material for each measurement. This keeps your results consistent.

- Proper equipment: Use tools like a protractor or a digital angle finder. These tools can make your job easier and more accurate.

- Repeat measurements: Take multiple measurements and average them. This reduces errors and gives you a more reliable result.

Common Mistakes

Even the best of us can make mistakes. Here are some common mistakes to avoid when measuring the angle of repose:

- Ignoring surface conditions: A wet or uneven surface can throw off your measurements. Always check the surface before starting.

- Using different materials: Different materials have different properties. Stick to one type of material for consistency.

- Rushing through the process: Take your time. Rushing can lead to inaccurate results.

- Not recording data: Always write down your measurements. This helps in keeping track and analyzing your results later.

Following these tips can make a big difference. I once rushed through a project and ended up with all sorts of errors. Learned my lesson the hard way! So take it slow, be consistent, and you’ll get it right.

Credit: www.researchgate.net

Frequently Asked Questions

What Is The Significance Of The Angle Of Repose?

The angle of repose measures the steepest angle at which a material remains stable. It’s crucial in construction, mining, and agriculture for designing safe slopes and storage.

How To Test For Angle Of Repose?

To test the angle of repose, slowly pour granular material onto a flat surface until a cone forms. Measure the height and base diameter of the cone. Use the formula: Angle of Repose = arctan(height/radius).

What Is The Angle Of Repose For Good Flow?

The angle of repose for good flow typically ranges from 30 to 35 degrees. This angle ensures materials flow smoothly.

What Is The Acceptable Angle Of Repose?

The acceptable angle of repose typically ranges from 30 to 45 degrees. This varies based on material properties.

Conclusion

Understanding the angle of repose is essential in various industries. It helps in designing safe storage solutions. Accurate measurement ensures efficient handling of materials. Use simple tools like a protractor or specialized equipment. Each material has a unique angle. This knowledge prevents spills and accidents.

Always consider environmental factors for precise readings. Now you know how the angle of repose impacts operations. Keep this in mind for better safety and efficiency.

Rakib Sarwar is a seasoned professional blogger, writer, and digital marketer with over 12 years of experience in freelance writing and niche website development on Upwork. In addition to his expertise in content creation and online marketing, Rakib is a registered pharmacist. Currently, he works in the IT Division of Sonali Bank PLC, where he combines his diverse skill set to excel in his career.